| This system is intended for low volume washing facilities with low solid loads. It will easily handle inconsistent flows as long as the flows don’t overwhelm the filters; it should be sized for the maximum flow or the flow be restricted to the filter’s capability. The number and sizes of the filters are chosen based on the type of solids to be removed. The final filter should be 100 microns as solids that pass through will not settle in pipes and block water flow. |

|

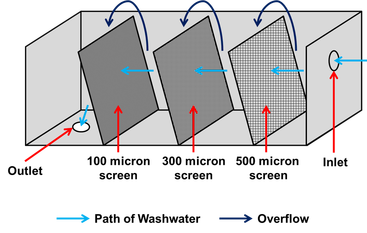

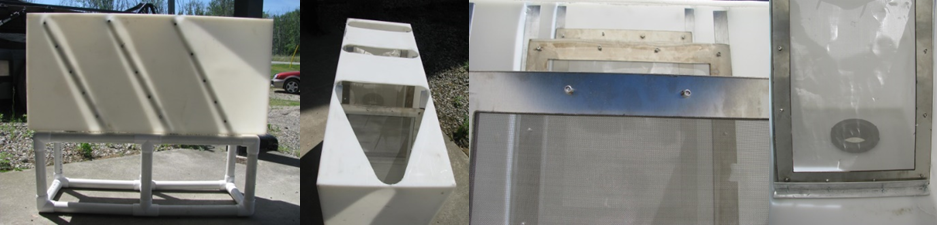

A progressive passive filter is simply a series of screens with increasingly smaller openings that trap solids as the water flows through the unit (Figure 1). It is designed to be a gravity-fed process and is best suited for low volume flows. The screens are installed on an angle and the water level gradually climbs as the screen becomes clogged. If the screen becomes fully clogged, the washwater can overflow into the next area. The filter can be easily cleaned by removing the screens and washing off the solids. Depending on the settling capability of the solids begin filtered, the tank holding the screens may also need to be rinsed. The advantage of this type of system is that it is a compilation of parts that can be inexpensively sourced. It can be built to any size necessary and be fitted into an existing tank system. The disadvantage is that it is not useful in a large-scale production and it does require manual operation and maintenance.

0 Comments

|

Project UpdatesFind articles on project-related topics here Archives

December 2016

Topics

All

Article TitlesIntroduction to

Watersheds Lake Simcoe Watershed Nottawasaga Valley Watershed South-Eastern Georgian Bay Watershed Water, Water, Everywhere? The Trouble with Muck: Size Lesson Learned: Bottom- up Aerator to Treat Washwater in Settling Tanks Phosphorus, the Environment, and Farming Nitrogen’s Impact on Air, Land, and Water Water-borne Pathogens and Food Safety Defining Dissolved Oxygen Filter Bags Demonstration Site Organic Matter Breakdown & Biochemical Oxygen Demand Dealing with Cloudy Water Hydrocyclone Demonstration Test What IS Muck? Demystifying Oxidation- Reduction Potential News Release "Technology Investigation: Filter Bags" Drum Filter Demonstration Site Decomposing With(out) Oxygen Flow monitoring Lesson Learned: Drum Filter Optimization Polders & the Holland Marsh Vegetable Washing Process Dry Soil Removal Ultrafiltration & Deionization Demonstration Site News Release "Technology Investigation: Ultrafiltration & Capacitive Deionization" Progressive Passive Filtration Dissolved Air Flotation Clarifying the Solid Removal Process Factsheet Reading Order News Release: "Technology Investigation: Coagulation & Flocculation" Self-Indexing Filter Monitoring Discharge Flows Settling Soil Mass Loading Calculations Lesson Learned: Technology Selection Electrocoagulation Auto-Samplers |

RSS Feed

RSS Feed