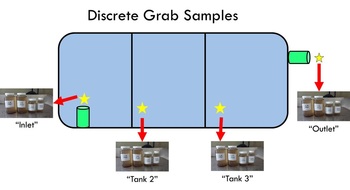

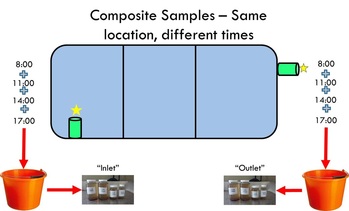

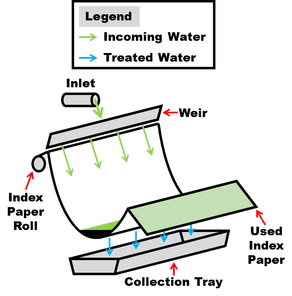

| When taking samples for specific purposes, it may be necessary to have a different plan for each intention. Discrete and composite samples serve different purposes in showing what happens at a single point or over a time span. Sampling over a longer time period such as a day should have a plan outlined prior to taking any samples. Discrete vs Composite Samples A discrete sample is one sample taken from a single point, at a specific time; this type of sample is also called a ‘grab’ sample. A composite sample is collected by combining grab samples from one location at different times, or samples from different locations at the same time and combined. Where discrete samples provide data from a snap shot in time, a composite sample can provide data spread throughout a day. Figures 1 and 2 show examples of how each type of samples are used. | |

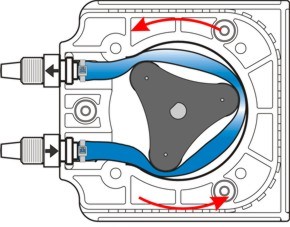

During the length of the HMGA Water Project, two types of sampling days were developed to give a clear picture of the water quality over a day and over three hour intervals. Regular sampling days involved taking one set of samples at each point of the treatment process with auto-samplers placed at the pre-treatment and post-treatment positions. Intensive sampling days were often bordered by regular sampling days and grab samples were taken every three hours along with the collection of the composite samples from the auto-samplers.

RSS Feed

RSS Feed