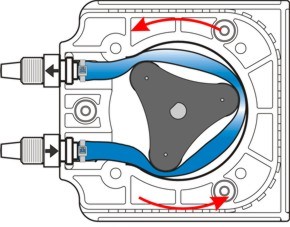

Figure 1: Water movement and composition of a peristaltic pump

Figure 1: Water movement and composition of a peristaltic pump Auto-samplers were introduced during the project in order to collect samples throughout a given production day. They are used to collect samples at various times without the user needing to be present. Grab samples were collected along with composite samples to provide a clear image of a day’s worth of washing.

HMGA Water Project & Auto-Samplers

The project utilized two types of auto-samplers: the Hach Sigma 900 and the MasterFlex E/C Composite Sampler. These two auto-samplers were utilized due to their ease of use and reliability. Both types of auto-samplers use peristaltic pumps to pull the water from the collection point through the hose to the bottle. All samples collected using the auto-samplers are composite samples; composite samples are a multitude of single samples combined. The composite samples were compared to results from manual grab samples.

The auto-samplers were set at varying intervals based on requirements of the day. On regular sampling days, the auto-samplers were set to take samples every half hour for twelve hours. Alternatively, the auto-samplers were set to draw a sample every ten minutes for three hours during the project’s intensive sampling days.

Peristaltic pumps

As discussed previously, the auto-samplers use peristaltic pumps to draw the water up the hose or tube. The pump works by pinching a flexible tube around rotors which rotate creating a suction on the water. As shown in Figure 1, the rotors move in a counter-clockwise rotation, creating suction, thus pulling the water up the tube.

Conclusion

The use of auto-samplers was integral to the success of the HMGA Water Project. They offer a user-friendly method to take samples that can be used in a variety of situations.

RSS Feed

RSS Feed