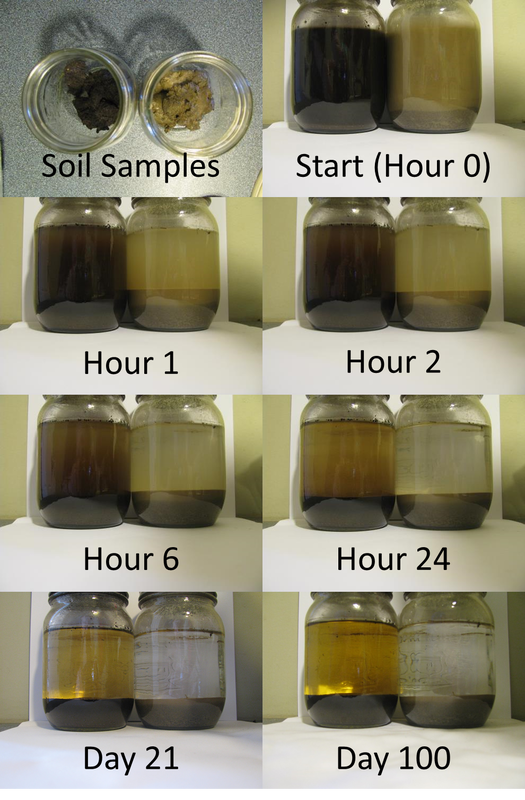

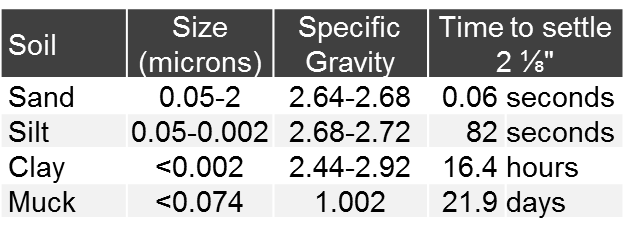

| Throughout the project there have been discussions about the different lengths of time it takes to settle different soil types. In general sand settles the quickest followed by silt, clay, and lastly, muck. To demonstrate this process, jar tests were done with a mineral and muck soil sample. Jar tests are simply soil added to water and left to settle. The depth of the water to the top of the sediment layer was measured as 2 1/8”. The test was evaluated by taking pictures of the two jars at regular intervals (Figure 1). Calculations were done to predict when the various soils would settle out of the water, shown in Figure 2. As expected, the order in which they settled was sand first, then silt, clay, and finally muck. The sand settled so quickly it was impossible to get a picture with it still in suspension. The silt followed soon after and then took a period of time to fill in the spaces between the sand particles. Clay can be seen in suspension in Hour 6 but has cleared in Hour 24. The calculations predicted that the muck would have settled in 22 days. While most of it cleared by the 21st day, the picture taken on the 100th day shows that there are still particles in suspension. Lastly, in both jars there is a layer of organic matter floating on the surface. These particles have made no downward movement through the time period. The jars will continue to be monitored to determine whether the colour clears from the jar containing the muck soil. | |

|

1 Comment

The HMGA Water Project evaluated coagulation and flocculation systems for removing fine solids from washwater. They were used in conjunction with large solid removal technologies and compared to other systems with no added chemicals. A summary of the tests and results are available in the article below.

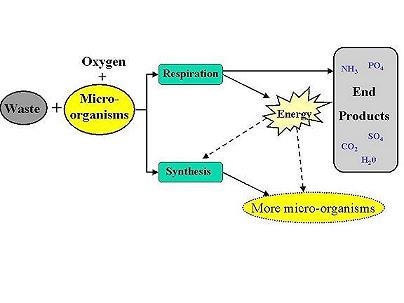

The sludge formed by settled solids in settling tanks may remain on the bottom for long periods, but decomposition will start as soon as the correct conditions are present. These include a food source (the solids), decomposers (a vast array of bacteria, fungi, etc.), and oxygen…or not. There are two types of decomposition: aerobic (with oxygen, Figure 1) and anaerobic (without oxygen, Figure 2). Aerobic decomposition turns organic matter, nutrients, and dissolved oxygen into biomass in the form of humus, nutrient compounds, carbon dioxide, and new decomposing microorganisms. This process creates energy; some is used by the organisms, but most is released as heat. Anaerobic decomposition is also called fermentation or putrefaction. This process is completed by microorganisms that require little to no oxygen (less than 5%) for survival. They break down organic compounds through a series of oxygen-free biochemical pathways and use the components for growth, reproduction, and to produce energy. The final product from the breakdown of organic material is biogas composed of carbon dioxide and methane. Anaerobic decomposition produces less heat but hydrogen sulfide gases can be released as a by-product. Both processes have advantages and disadvantages. Anaerobic creates little heat and less solid end-product as much is released as gas, however, it also quite odorous. The heat produced by aerobic decomposition sterilizes the final solids of pathogenic organisms and, if it can be captured, it can be utilized. It does require specific heat and oxygen ranges to operate efficiently. One major factor to be considered when determining which system to promote in a settling tank is the time of the decomposition process. Aerobic decomposition can occur much faster; the specific multiplication factor is dependent on the source material and active organisms. References

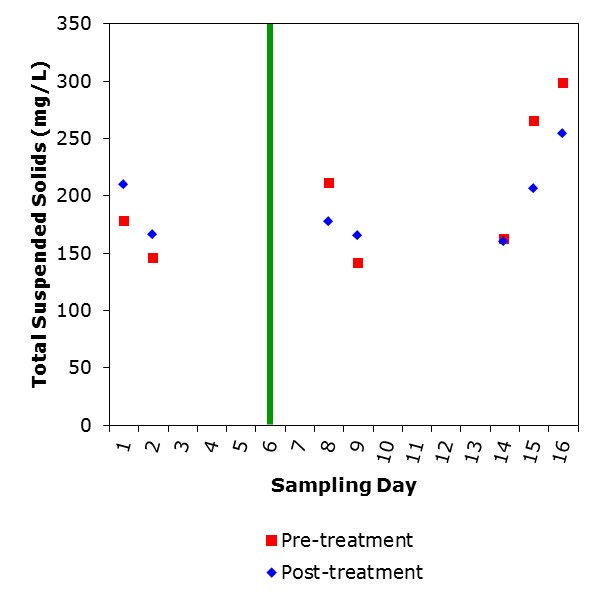

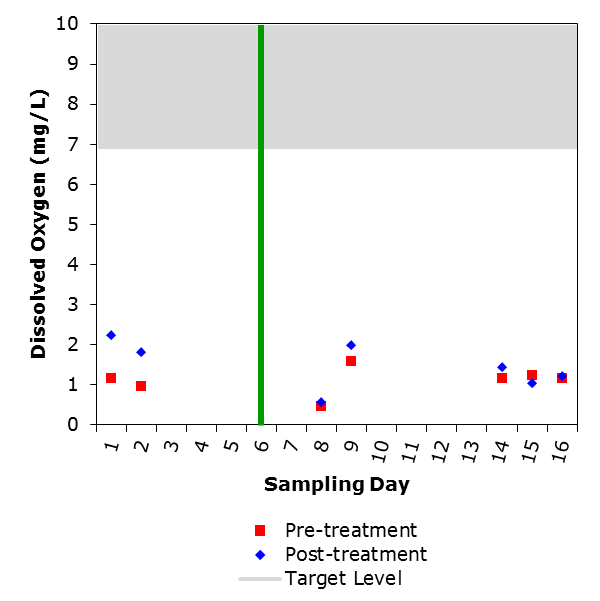

Not every solution implemented results in success. Those various mistakes and failures are discussed here as well as the lessons learned from them. Goal: Decrease Total Suspended Solids (TSS) while increasing Dissolved Oxygen (DO) concentrations in a settling tank Solution: Installation of a Bottom-up Aerator. A Bottom-up Aerator works by pumping compressed air down to a diffuser (Figure 1) situated on the bottom of the tank. The air is released through the diffuser as bubbles which work their way to the surface. As the bubbles rise, the oxygen is dissolving into the water. Problem: The primary goal of the settling tank is to remove suspended particles by sedimentation and removal of clear water at the surface. The bubbles surfacing from the aerator interrupted this process by keeping the particles in suspension (Figure 2). Also, water testing results showed that there was no significant positive impact on the DO (Figure 3). Discussion: The system failed to increase the DO in the water and had a negative impact on the TSS. While a Bottom-up Aerator is suitable in other situations where particle settling is not a concern, it was not appropriate for resolving this problem. It was removed and replaced with a Surface Aerator.

References

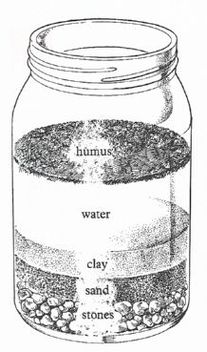

A common test, called the Mason jar soil test, is suggested for home gardeners to decipher their soil type. The basic concept is to put water and a scoop of the soil into the jar, shake to thoroughly mix the soil and water, and let it stand. The sand will settle to the bottom first, followed by the silt, and finally the clay will fall out of suspension. The sand will settle in a minute, the silt will take a few hours, and clay will stay in suspension for a full day. The soil type is then determined by measuring the depth of these layers. But there’s more to soil than sand, silt, and clay. The fine organic matter particles are the last to sink and the large particles will just stay afloat. Diagram (left) and example (right) of a Mason jar soil test [Picture sources: (l) Pinkney (2010) and (r) Three Easy Soil Tests (2010)] The vast majority of soil types involve varying amounts of sand, silt, and clay with a minimal amount of organic matter. Muck soils are unique in that they have anywhere between 20 and 80% organic matter.

Settling ponds or tanks, a scaled-up version of a Mason jar, is a method used to remove suspended solids from different types of wastewater. The wastewater is pumped into a large holding tank where it is held. The heavy particles will fall out of suspension and sink to the bottom leaving clear water to exit the pond. But, as the Mason jar test shows the time that wastewater needs to stay in the pond depends on the soil type. So, settling ponds, whose entire purpose is to give particles time to sink, and muck, a soil type resistant to sinking, are a mismatched pair. They can still work together if the additional time for the muck to settle out is taken into account or as one part of a multi-step treatment process. References

|

Project UpdatesFind articles on project-related topics here Archives

December 2016

Topics

All

Article TitlesIntroduction to

Watersheds Lake Simcoe Watershed Nottawasaga Valley Watershed South-Eastern Georgian Bay Watershed Water, Water, Everywhere? The Trouble with Muck: Size Lesson Learned: Bottom- up Aerator to Treat Washwater in Settling Tanks Phosphorus, the Environment, and Farming Nitrogen’s Impact on Air, Land, and Water Water-borne Pathogens and Food Safety Defining Dissolved Oxygen Filter Bags Demonstration Site Organic Matter Breakdown & Biochemical Oxygen Demand Dealing with Cloudy Water Hydrocyclone Demonstration Test What IS Muck? Demystifying Oxidation- Reduction Potential News Release "Technology Investigation: Filter Bags" Drum Filter Demonstration Site Decomposing With(out) Oxygen Flow monitoring Lesson Learned: Drum Filter Optimization Polders & the Holland Marsh Vegetable Washing Process Dry Soil Removal Ultrafiltration & Deionization Demonstration Site News Release "Technology Investigation: Ultrafiltration & Capacitive Deionization" Progressive Passive Filtration Dissolved Air Flotation Clarifying the Solid Removal Process Factsheet Reading Order News Release: "Technology Investigation: Coagulation & Flocculation" Self-Indexing Filter Monitoring Discharge Flows Settling Soil Mass Loading Calculations Lesson Learned: Technology Selection Electrocoagulation Auto-Samplers |

||||||||

RSS Feed

RSS Feed