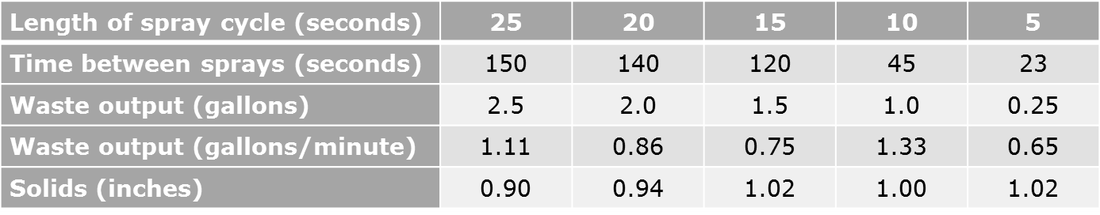

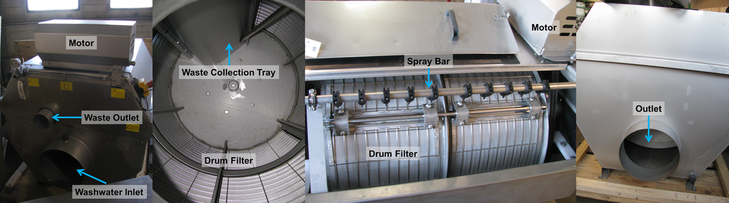

Filtration systems are not always a simple installation. Technologies require some manipulation to ensure that they are functioning at their maximum efficiency. The drum filter that was installation is one example. It succeeded in taking in washwater and filtering it through the screen. It was successful in rotating the barrel and spraying off the waste into a collection tray. However, initially the output of the collection tray contained excessive amounts of water. As the goal is to have a sludge-like material with the least amount of water possible to limit amounts of waste to dispose, adjustments were in order. The drum filter is able automated to rotate and spray on a regular schedule; the purpose of the optimization process is to find the setting that produces the most concentrated waste stream.

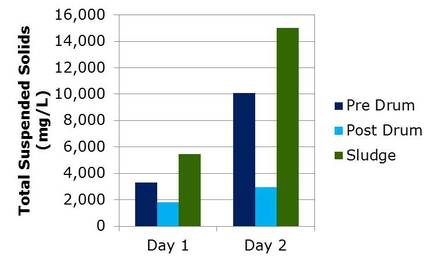

| Prior to optimizing the cycle setting, the change in total suspended solids between pre and post drum samples was 46%. The drum filter was run using the 5 second spray cycle setting and samples of the pre drum, post drum, and sludge were taken. After changing the setting, the change pre and post drum was 71%. Through manipulating the spray cycle, the efficiency of the system was greatly increased. |

RSS Feed

RSS Feed