First, all the applicable terms need to be defined:

- Clarification: this term can be used to describe the overall process of removing fine particles from water

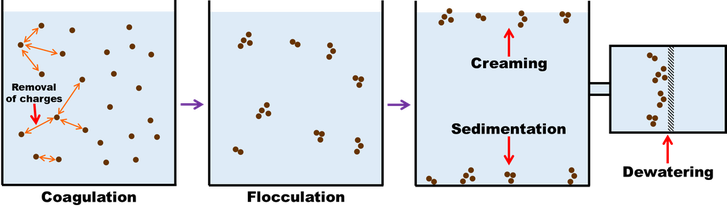

- Coagulation: is the act of neutralizing the charges of particles that allow them to repel each other.

- Flocculation: occurs when neutralized (coagulated) particles are brought together to form larger compounds called ‘flocs’

- Sedimentation: separating solids from water through settling

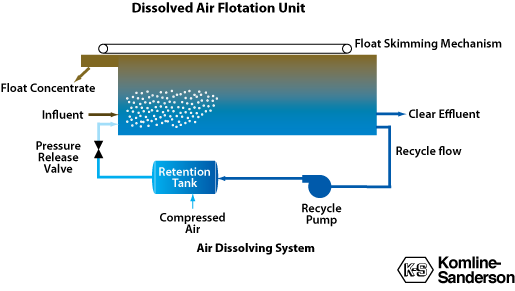

- Creaming/Flotation: separating solids from water by floating them to the surface

- Dewatering: separating solids from water through filtration

The first stage in the clarification of water is coagulation. When small particles are involved, coagulation usually has to be achieved through the addition of chemical aids. The next stage is flocculation and whether or not another chemical is required here is dependent on the particles and the desired speed of floc formation. The final stage is separating the flocs from the water.

- Tramfloc, Inc. (2014). Selecting Polymers, Jar Testing Procedures. In Flocculants. Retrieved March 14, 2016, from http://tramfloc.com/polymers-selection-jar-testing-procedures/

- GE Power & Water. (2012). Chapter 05 - Clarification. In Handbook of Industrial Water Treatment. Retrieved March 14, 2016, from http://www.gewater.com/handbook/ext_treatment/ch_5_clarification.jsp

RSS Feed

RSS Feed