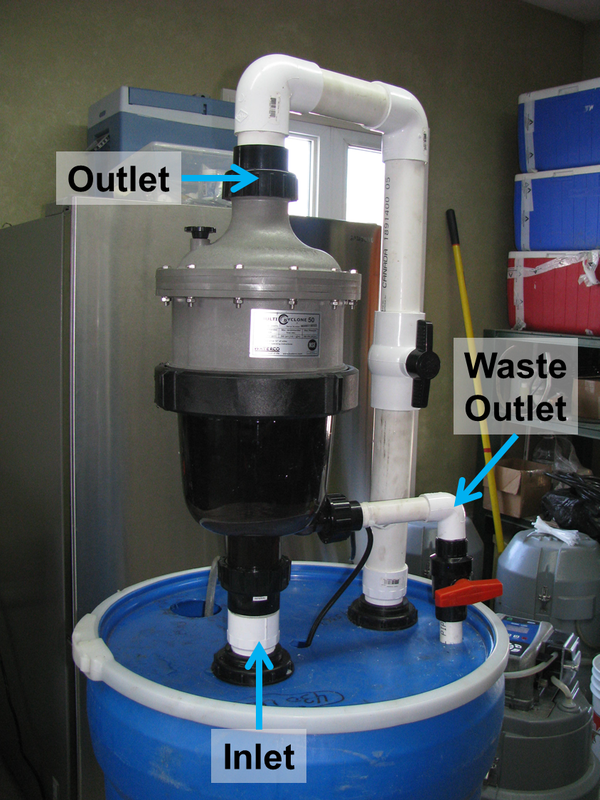

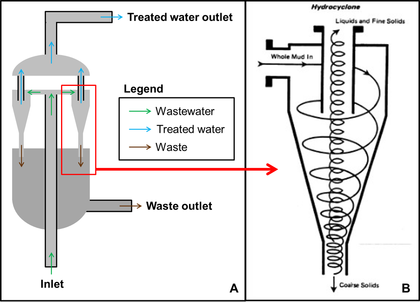

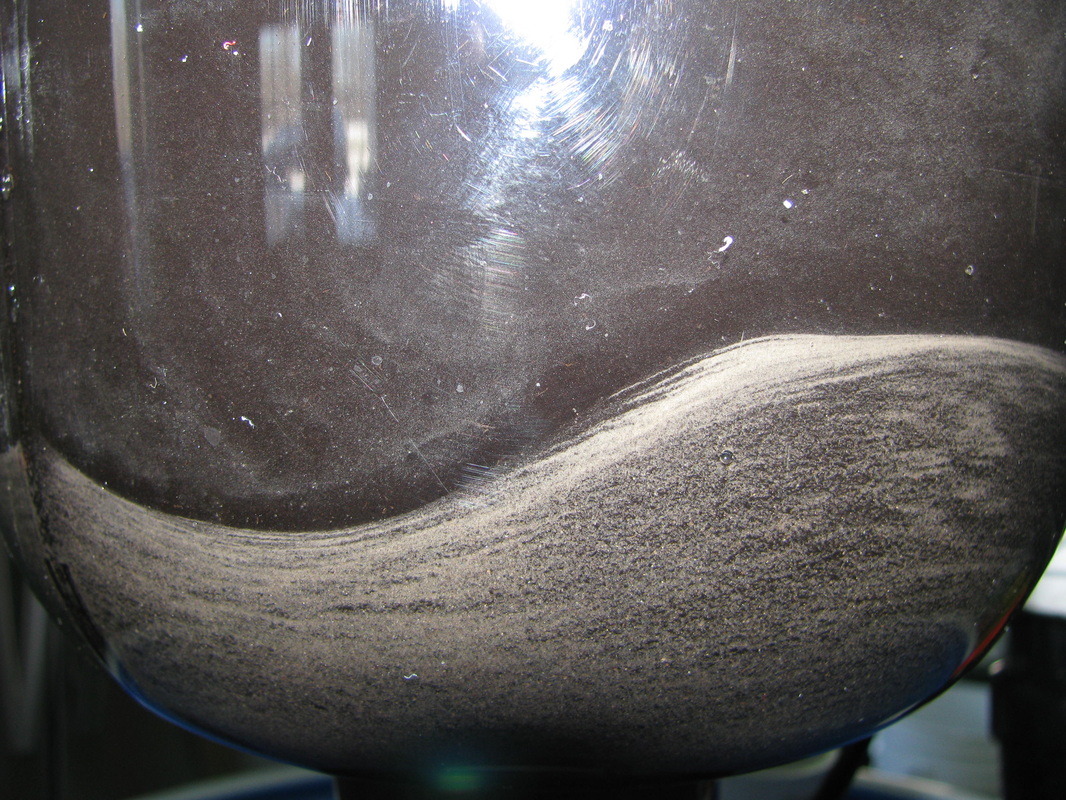

| A small-scale hydrocyclone was set up in a test rig and a trial was performed to determine its potential for removing fine solids from vegetable washwater. The term ‘hydrocyclone’ refers to a cone-like structure where waste is separated out of wastewater. They can be run singularly or in a parallel system; the piece of equipment tested employed several small hydrocyclones running in parallel within a larger unit. The unit was installed on top of a barrel with an inlet, outlet, and waste outlet so that the water could cycle through the system (Figure 1). A solution of muck and water was prepared; 1 L of muck was sieved through a 200 micron screen to remove roots and coarse solids and added to 150 L of water. |

The results of this test will be shared in upcoming article.

References

- CSI. (2009). FAQ. In Hydrocyclone. Retrieved March 26, 2015, from http://www.hydrocyclone.com/faq.htm

- TangShan Dachuan Machinery Co., Ltd. (2013). Working Principle of Hydrocyclones. Retrieved March 6, 2015, from http://shaleshakerdc.com/working-principle-of-hydrocyclones/

RSS Feed

RSS Feed